3D Printing Without Limits: BAC’s Breakthrough with Drywise

No compromises, even with 98h prints: Now BAC prints better

Briggs Automotive Company (BAC) Ltd is the British manufacturer behind the world’s only road-legal, single-seater supercars – the BAC Mono and BAC Mono R. The Liverpool-based business was founded in 2009 by brothers Neill and Ian Briggs, who set about delivering a pinnacle road vehicle that offers the most authentic and purest driving experience possible.

Mono and Mono R implement the very latest racing technology and are highly regarded by customers and critics alike as the ultimate pieces of sporting equipment for the art of driving. They focus solely on the person behind the wheel, race cars for the road that can be described as A-to-A vehicles, rather than A-to-B – forget the destination; these models are all about pure driving pleasure.

Designed, engineered, and managed by experts with extensive backgrounds in leading global automotive, high-end supercar, and motorsport brands, Mono and Mono R, are luxury products that owners can tailor to fulfil their needs and desires. From performance to personalised vehicle aesthetics, drivers are offered a truly bespoke commissioning experience and customer journey. Every single car rolled out of the BAC factory is a ‘One of a Kind’ creation. To achieve their ambitious goals, they rely heavily on 3D printing for prototyping and production of high-performance components. Recently, BAC integrated the innovative Drywise inline filament dryer into their workflow, and the results have been nothing short of transformative.

BAC exports 90% of the cars it produces to more than 45 different countries across five different continents – and counting. The company’s carefully selected, highly specialised dealer network across America, Asia and Europe caters to an ever-growing global demand for Mono ownership and servicing.

The Challenges

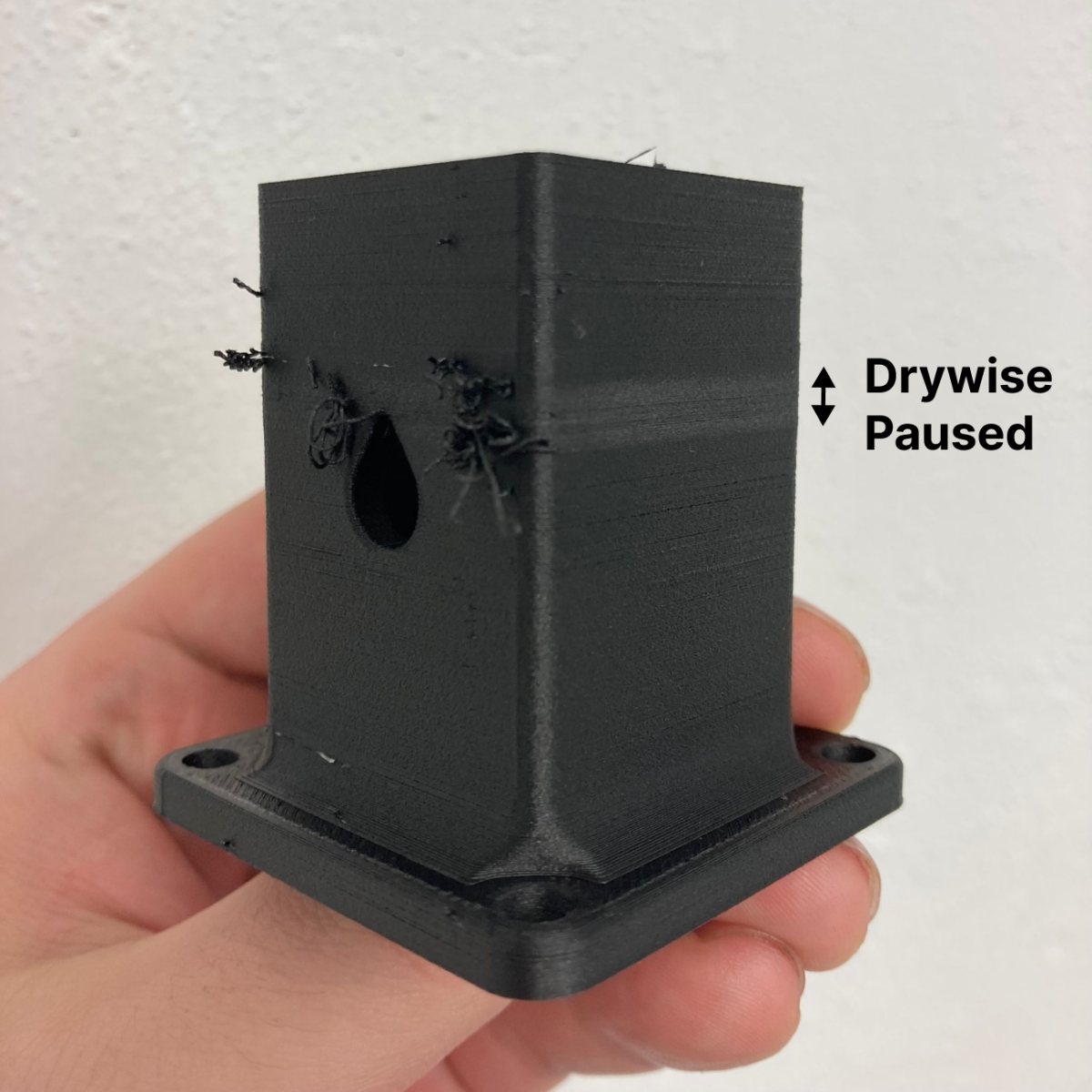

Traditional filament drying methods have long posed challenges for manufacturers. They are often time-consuming, inconsistent, and energy-intensive, which can lead to wasted material, failed prints, and inefficiencies in production. BAC’s extensive 3D printing projects, some lasting over 98 hours, require unparalleled reliability and precision. Achieving consistent print quality for such long durations was a persistent challenge until they started using Drywise.

The Solution: Drywise Inline Filament Dryer

Drywise brings advanced drying technology directly to the 3D printing process. Unlike traditional methods, it continuously dries filament during printing, ensuring optimal material condition without downtime. For BAC, this innovation meant:

Countless Hours Saved: No need for pre-drying filament for hours or days. Drywise’s inline drying eliminates this step entirely, allowing BAC to focus on printing instead of preparation.

Unmatched Print Quality: Drywise ensures consistent filament condition throughout the entire print job, even during lengthy prints exceeding 98 hours. This consistency translates to impeccable surface finishes and part accuracy, critical for BAC’s high-performance automotive components.

Energy Efficiency: Traditional drying methods consume significant energy over extended periods. Drywise’s targeted, on-demand drying technology minimizes energy usage, contributing to BAC’s sustainability goals. For example, a traditional filament drying oven might consume around 500 watts per hour. Left overnight, for an 18-hour drying period, it would total 9 kWh per drying cycle. In contrast, Drywise operates at an average of 50 watts during active printing, thus even over 98 hours of operation, it consumes only 4.9 kWh. This represents a substantial energy saving of over 45%.

Compared with cheap filament dryers, that still don’t manage to fully dry most technical materials, the energy savings could potentially be as high as 300%.

Reduced Waste: By ensuring filament is always in peak condition, Drywise significantly reduces material waste caused by failed prints or inconsistent extrusion.

The Results

Since adopting Drywise, BAC has reported exceptional improvements in their 3D printing process. Not only have they experienced significant time and energy savings, but they’ve also achieved unprecedented reliability for their long-duration prints. This has allowed them to meet tight production deadlines while maintaining the world-class quality standards their brand is known for.

Drywise has proven to be a game-changer for Briggs Automotive Company. By streamlining the filament drying process, ensuring consistent print quality, and saving both time and energy, Drywise is helping BAC push the boundaries of what’s possible in automotive design and manufacturing. For any organization seeking to elevate their 3D printing capabilities, Drywise is a proven and indispensable tool.