Filament Drying Perfected

2 Year Warranty

Wordwide Delivery

Support

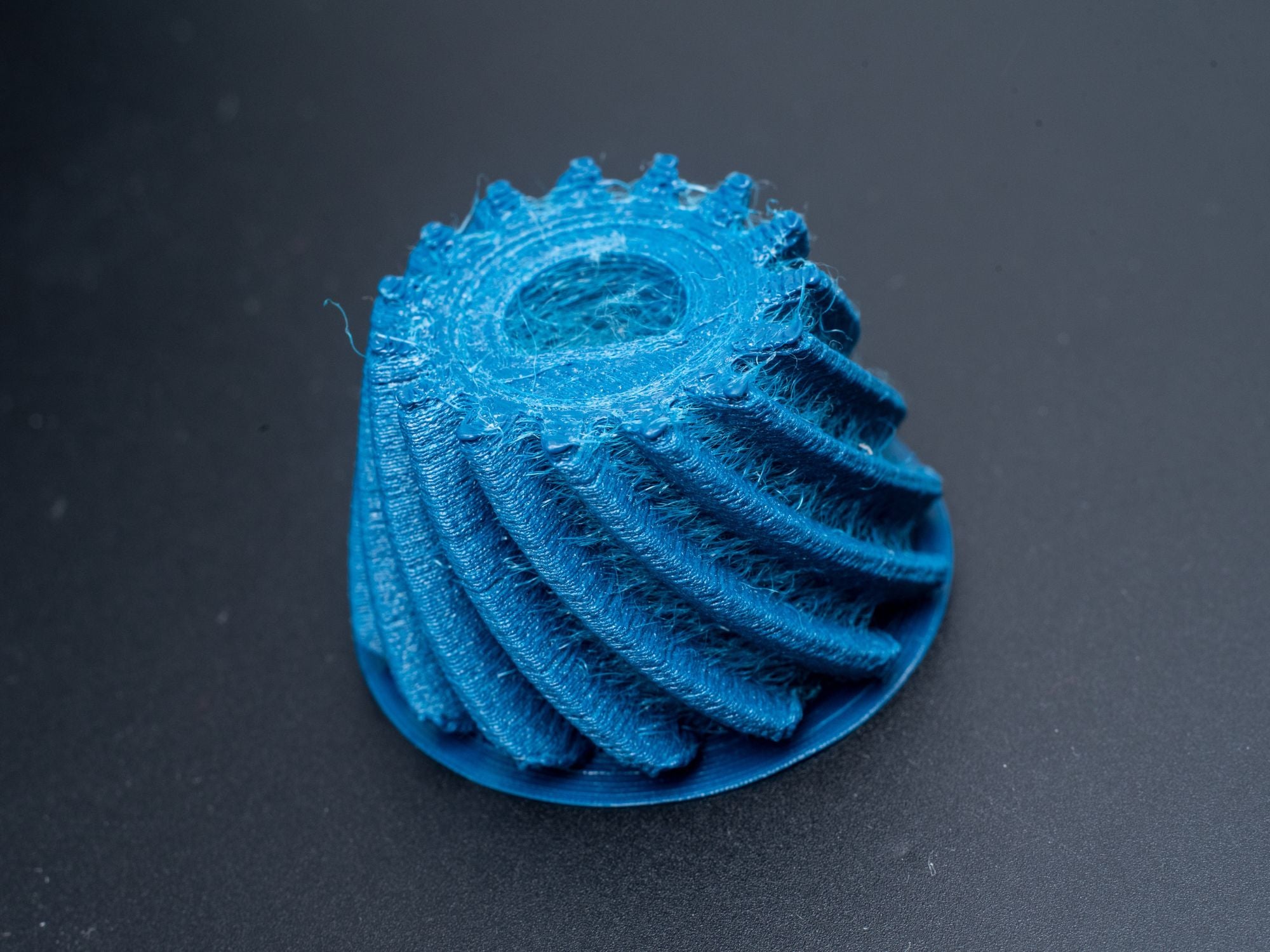

See the Drywise Difference

Without proper drying

With Drywise

Use the left and right arrow keys to navigate between before and after photos.

Core Benefits

Stronger Parts

Reduce weak bonds and surface defects caused by moisture.

Correct Dimensions

Improve repeatability and hit tighter tolerances.

Best Sruface Finish

Cleaner layers with less stringing and pitting.

Save Time & Cost

Fewer reprints, less operator time, smoother workflow.

Easy Handling

No need to be a material expert to achieve best results.

Repeatable Results

Same results irrespective of changes in operator, material, or environment.

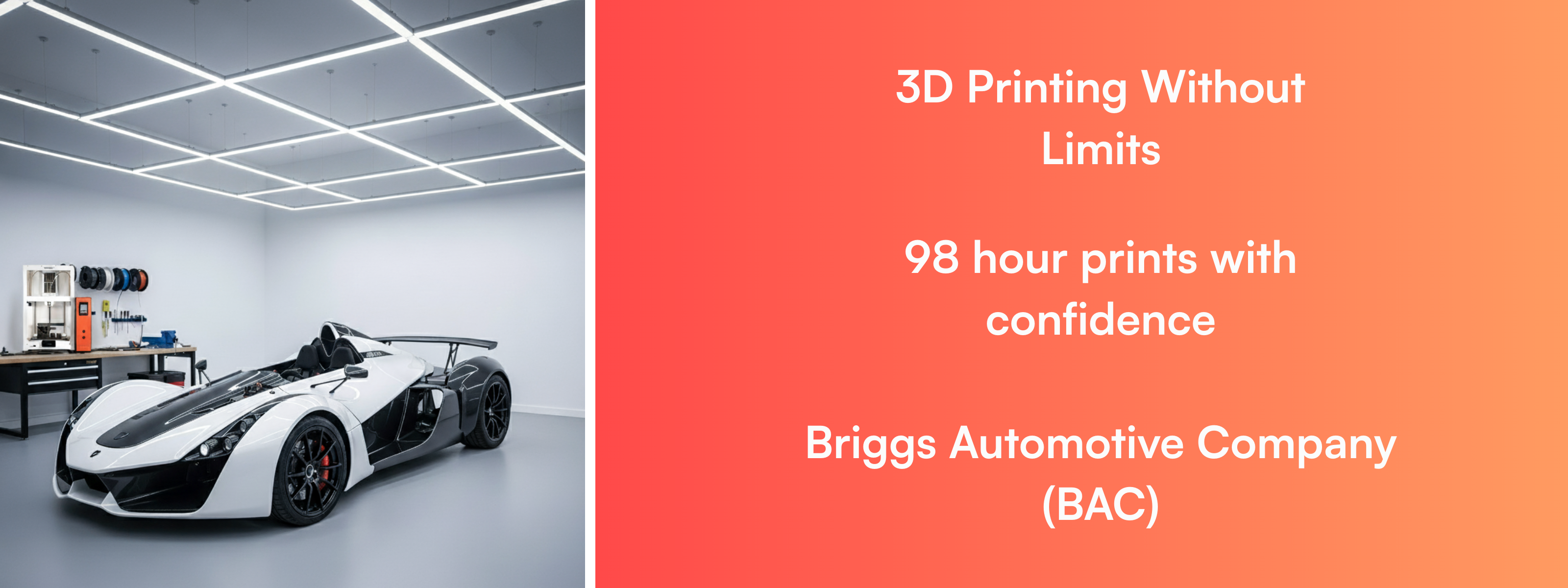

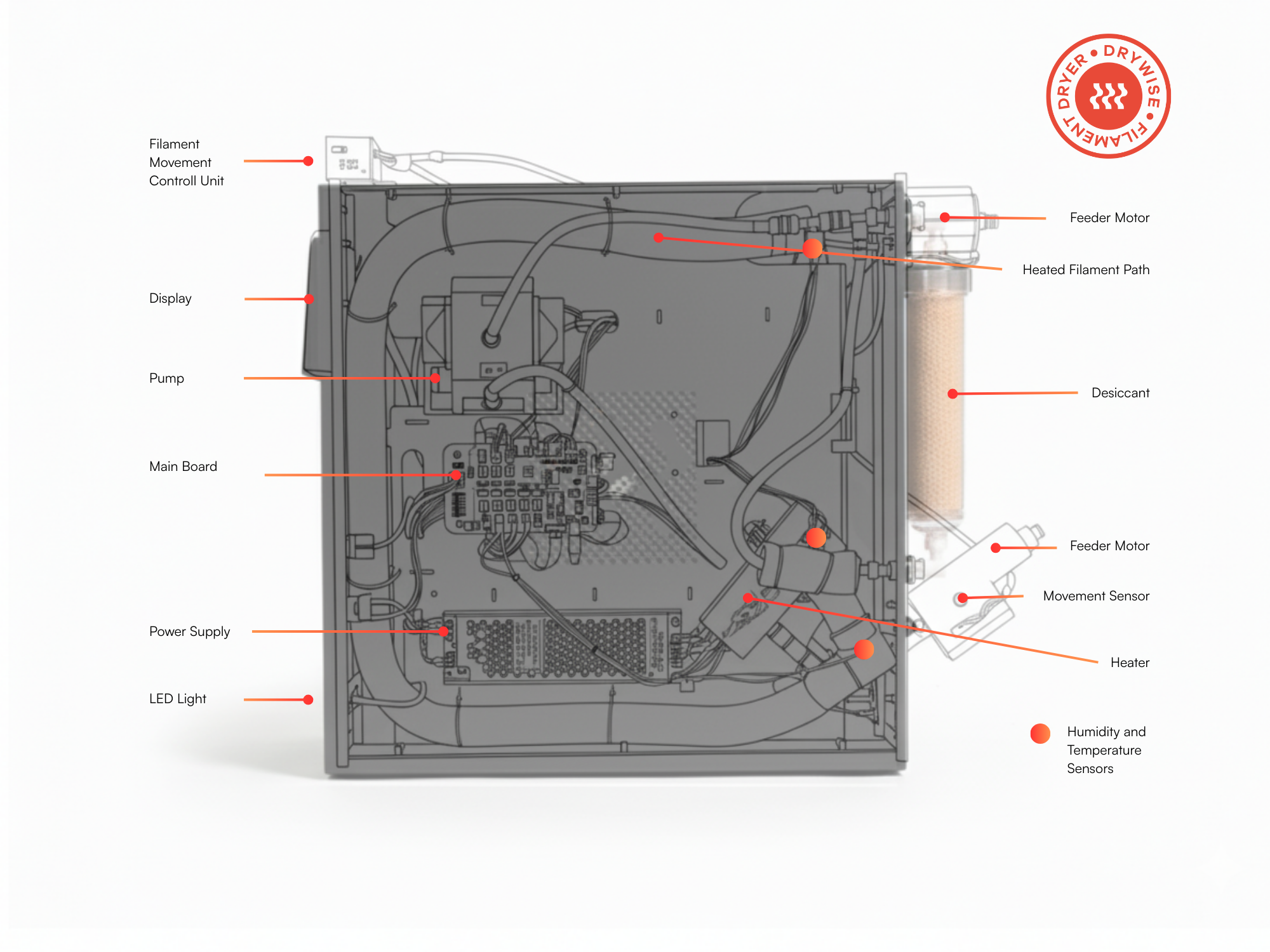

Engineered for Professional Results

Before

After

Use the left and right arrow keys to navigate between before and after photos.

Built for Real-world Printers and Materials

Printers

- Ultimaker

- Raise3D

- Anisoprint/Fiberforce

- Markforged*

- Prusa

- Bambu Lab

- And other

Materials

- Nylons (Polyamides)

- PEI (Ultem), PEEK, PEKK

- PETG

- TPU

- PC blends

- Support materials

- Other hygroscopic filaments

Notes

- Works well with large 3kg+ spools.

- Custom plug-in with Cura

- Custom start gcode for BambuLab printers, Creality and others

Our Case Studies

Featured Articles