Valuable time lost planning material drying and pre-drying the material for hours, or even days.If the filament is not correctly dried, it could result in costly delays in scheduled production.

Effects of Moisture

And the hidden costs of incorrect / traditional drying

-

+ Lost Time and Longer Time to Part

-

+ Material Wastage and Degradation

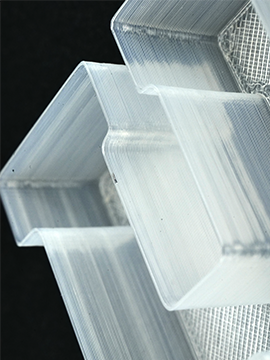

Incorrect drying leads to inconsistent prints with weak mechanical properties and poor aesthetics that end up discarded or fail prematurely. Furthermore, multiple heat cycles and/or incorrect drying settings degrade the material quality.

-

+ Machine Downtime

Full utilisation of the machinery at hand is very difficult as filament needs to be planned and dried days in advance. Also, multiple failed prints and higher probability of hot-end jams due to incorrect drying, means there is less effective utilisation of available machine time.

-

+ Print Inconsistencies

Even when following standard operating procedures, different results can be expected. There are many unknowns that affect the process, initial humidity in the filament, relative humidity of the environment, rate of moisture loss in the oven, etc...

-

+ Bulky, Unsafe and requiring Multiple Devices

Ovens are bulky and the easy access to really hot parts makes them inherently unsafe, especially in an office or school environment. Cheap dryers can easily catch fire, as in order to keep the cost down, no safety measures are present. After drying, other devices are still needed to keep the filament in a good state.

3D printing filament needs drying

Wet filament results in inferior print quality.

DRYWISE

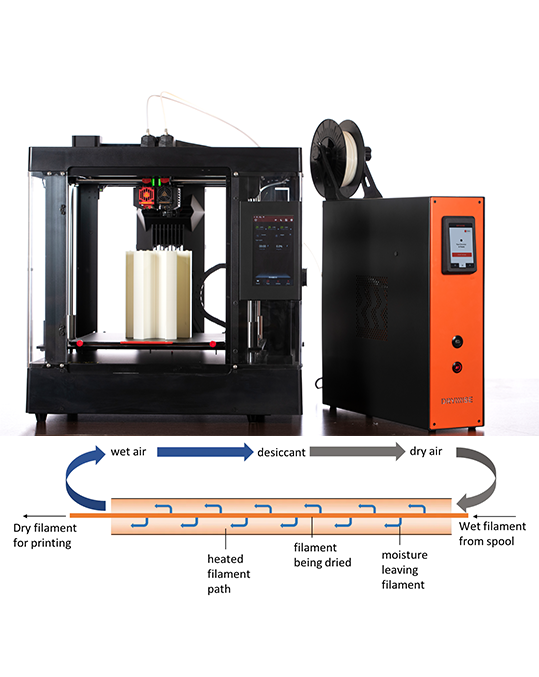

Inline Filament Drying for Ultimate Material Quality Control

-

+ Significant Time Savings and Shorter Time to Part

Valuable time is gained thanks to the quasi instant drying, a feature of the in-line drying architecture. Further, the pre-calibrated settings for certified materials eliminate guesswork and remove the need to research settings.Drying in-line is much more efficient and effective, eliminating prolonged drying times as it dries during printing.

-

+ Minimised Material Wastage

Guaranteed excellent material quality control at all times during the printing process, whilst Drywise is active.By just drying the material once just before printing, material quality is always maintained.

-

+ More Machine Uptime and Improve Efficiency

No pre planning is needed meaning getting full utilisation of your machines is now possible, more easily.Less failed prints and lower nozzle jams also result in a higher machine throughput.

-

+ Lower Energy Costs

Due to the superior drying efficiency and the fact that only the required filament is dried at any time, Drywise is much more energy efficient. Also, it does not require any auxiliary devices to maintain the filament in a good state.

-

+ Consistent, Best Quality Results

Drywise eliminates uncertainties when it comes to material quality control, respecting the material whilst giving the best performing parts.

-

+ Safe, Streamlined, Reliable Device

Drywise, with its inline architecture, dries the required filament just in time for printing, meaning that no further maintenance devices or anything else is needed.It is designed with safety in mind to offer reliability and peace of mind.

Elevate your Additive Manufacturing

DRYWISE

How it works.