Moisture in FFF Filaments, what are the Drawbacks?

Do you need to dry your printing materials prior to processing? Why? The Drywise team has conducted a number of tests on Nylon filaments to determine how necessary it is to dry your filaments. The results might surprise you!

Why is Drying important?

Any experienced 3D printing engineer can attest that most thermoplastic materials tend to absorb moisture. For most materials, this can affect the printing process especially since these materials can become significantly wet in a matter of days if not hours. One material that is especially prone to absorbing moisture is Nylon, however other materials such as PET, Polycarbonate, and high-temperature materials such as PEEK, PEKK, and PEI also tend to suffer from this issue.

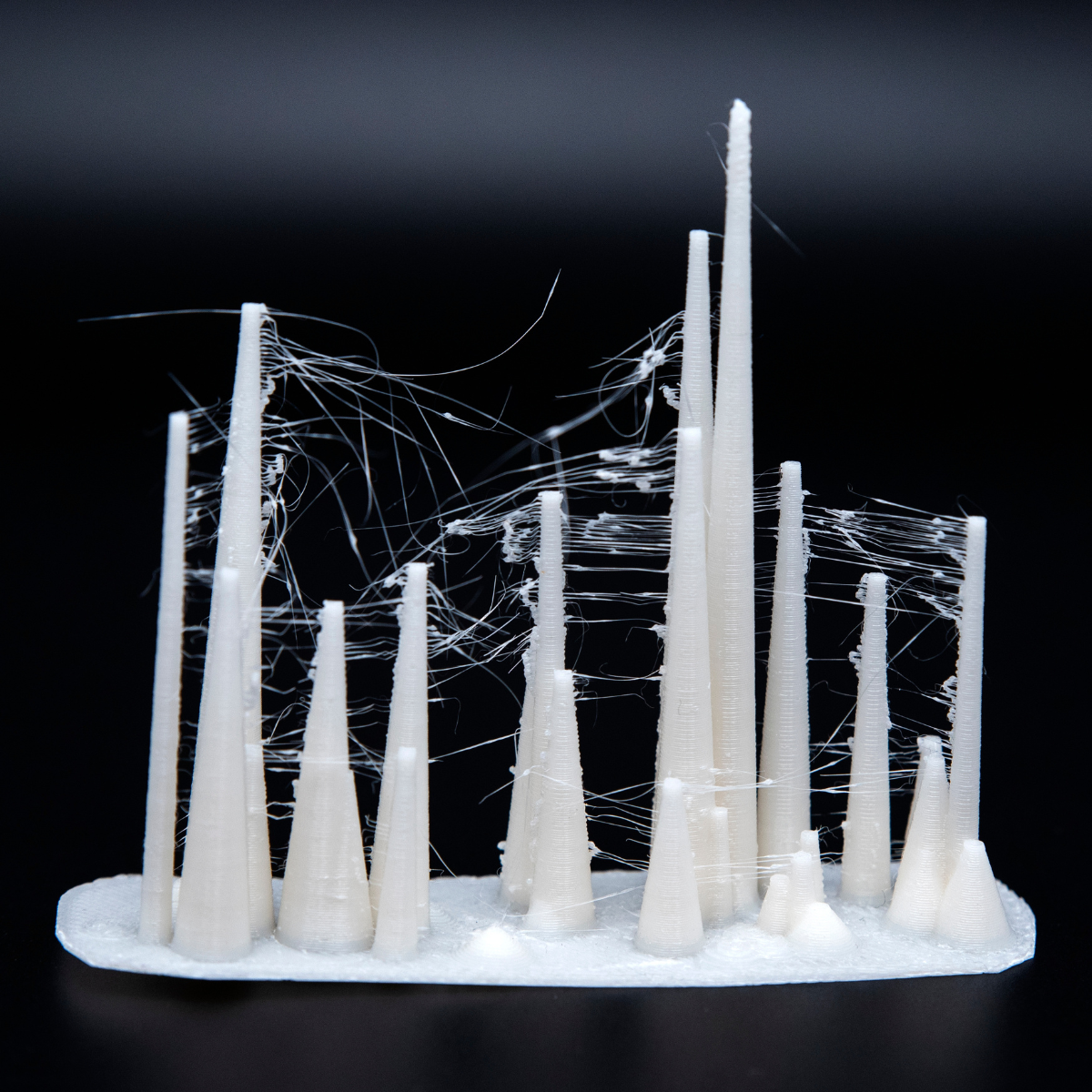

Hissing and popping sounds are the first tell-tale signs that one is printing with wet filament. This happens because the water absorbed by the plastic is very quickly vapourized by the heated nozzle. As a result of this rapid phase change, inconsistent material extrusion and nozzle blockages are common occurrences.

This inconsistent material extrusion will have several visible effects on your prints. Stringing and oozing in prints will be more pronounced as the added pressure in the hot end results in less control over the amount of extruded material. The strength of the print will also be negatively affected. As water changes to steam, lots of voids (bubbles) will be trapped inside the filament and ultimately the print, reducing layer adhesion and the overall part strength.

The effect of moisture on FFF prints

The image below shows the effect of different moisture levels on the print quality of two materials. On one side is a typical neat PA6/66 copolymer and on the other, a CF filled nylon. These materials were first hydrated in a hydration chamber at 75% RH, after which they were dried in the oven until they reached the target humidity levels.

From the figure above it can be clearly observed that for the neat nylon material, a moisture content of around 0.75% is enough to start causing artifacts on printed parts. On the other hand, for the CF-filled filament, it can be seen that even at very low moisture levels of around 0.34 %, the material still tends to show printing artifacts. In fact, from our experience with drying filaments, we have observed that generally filled materials tend to start showing printing artifacts at lower moisture levels.

Even freshly opened spools can contain significant amounts of moisture

In an ideal world a newly opened spool of filament contains as little moisture as possible so that the user can start printing the material straightaway. Unfortunately, this is not always the case. In some instances, the production process of a filament will introduce moisture to the material. Material manufacturers need to take special precautions when packaging filament to ensure that it is packaged with the lowest amount of moisture possible. However even after taking extra precautions the material might pick up significant amounts of moisture if it is improperly packaged or kept in storage for a long time before being used.

We took a sample of 32 filament spools (20 different nylon materials) of neat and filled nylon filaments from 9 well-known brands and measured their moisture content out of the box. The results of these measurements were surprising. Out of 19 neat filaments, 9 of them had moisture contents around or above 0.75 %. Furthermore out of 13 filled filament types, 9 of them had a moisture content of above 0.5%. As discussed previously and from our in-house experience, at these moisture contents and above, nylon filaments tend to start showing printing artifacts due to the moisture present.

Filaments can absorb moisture very quickly!

The figure below shows the moisture pickup of two newly opened spools of filament left outside in atmospheric conditions (22 °C, 57 % RH). Filament A started from 0.65% humidity and gained 0.12 % moisture in just 1 day. At this level, the filament already starts showing some printing artifacts. After another couple of days, the filament exceeds 1% humidity. Beyond this point, the filament starts showing severe printing artifacts and the filament would need to be dried before it can be printed.

Filament B is a Nylon copolymer having a lower moisture uptake than other PA6-based filaments. In fact, it gains moisture more slowly than Filament A. Nonetheless the filament still reaches 1 % after 7 days, originally starting at 0.5 % humidity. Therefore, if the filament is not dried or stored properly, it will still start showing printing artifacts in around a week!

What does this mean?

From the data gathered above, it can be concluded that when it comes to printing nylon filament, one needs to dry the filament before use or shortly after, and, keep it dry. There are several filament drying and storage solutions that will be discussed in a future article, all of which have their drawbacks.

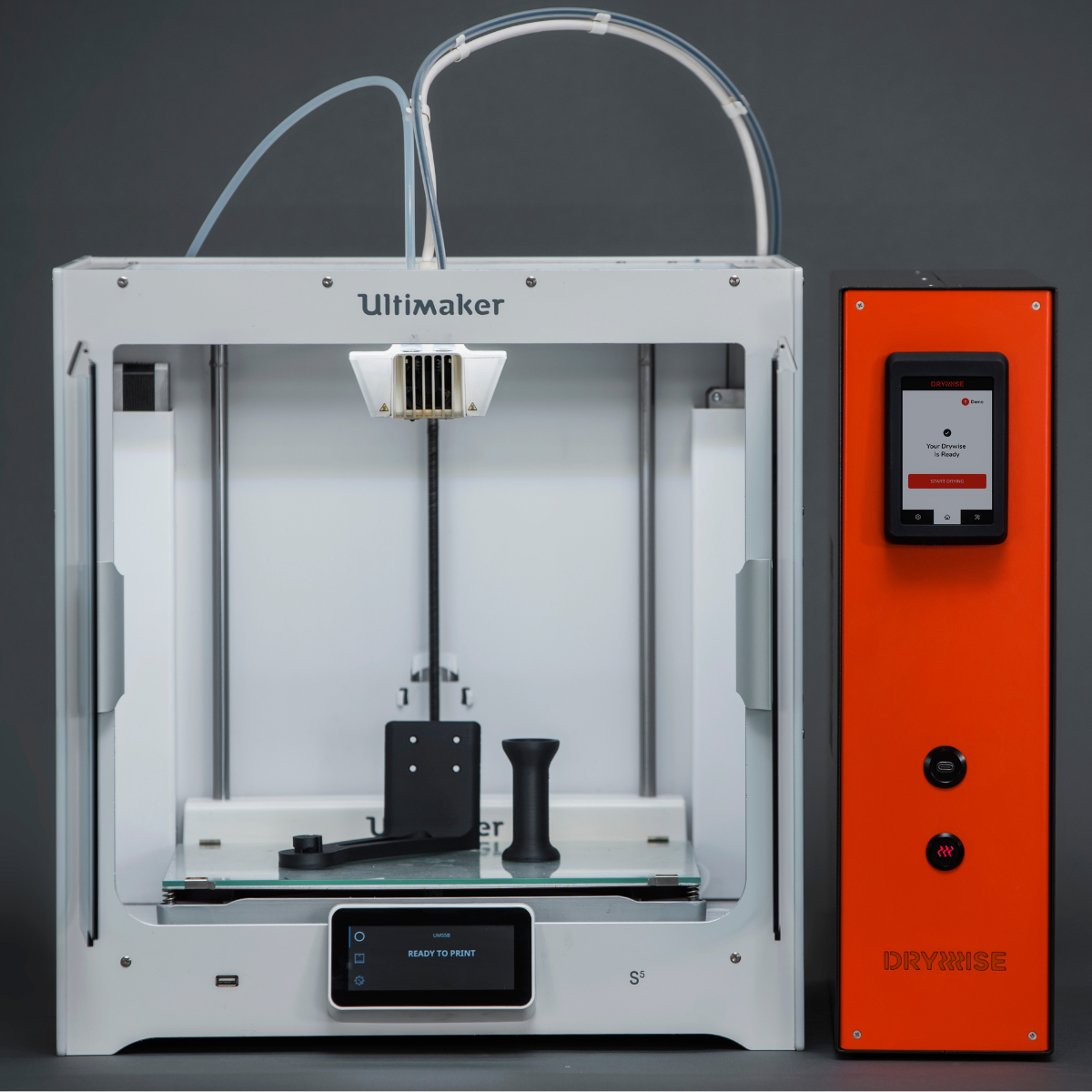

Drywise aims to address these issues since it is drying the filament in-line. This means that Drywise only dries the portion of the filament as it is being fed into the printer. The printer thus is being fed with freshly dried filament as it is printing ensuring consistently dried filament. As a result, Drywise addresses both the need for drying filament and also the need of keeping it dry. Furthermore since the spool is not housed in the unit itself, any spool size can be used with Drywise.