Enhancing Surface Finish and Dimensional Accuracy in FDM 3D Printing with In-line drying

Exploring the Impact of Filament Moisture Content on Surface Aesthetics and Print Dimensions in FDM 3D Printing

Surface Finish and Dimensional Accuracy

Fused Deposition Modelling (FDM) is a widely used 3D printing technique that employs thermoplastic filaments to create solid objects layer by layer. However, the presence of moisture in these filaments can significantly impact the dimensional accuracy of FDM prints. The generation of steam during extrusion leads to inconsistent extrusion and incorporation of voids, distorting the extruded material and consequently the overall geometry of the finished part. This can result in layers of the print becoming misaligned, leading to inconsistent thicknesses, and compromising the overall quality of the printed parts.

A recent study by Thought3D has shed light on how in-line drying can significantly improve the surface finish and dimensional accuracy of FDM prints. The study compared a calibration part printed with untreated wet nylon at 3% humidity and the same part printed with the same material but treated with Drywise in-line dryer – see Figure 1 below. The part printed using Drywise showed superior surface finish, while the untreated part had a poor surface finish and showed stringing and oozing on the pillars and in the holes.

Figure 1: Print assessing dimensional accuracy in untreated nylon with 3% humidity (left) and nylon with 3% humidity that has been treated with Drywise in-line dryer (right).

The pillars were each measured at three different heights while the holes were measured at three different axes to assess the effect of moisture on the dimensional accuracy of the printed parts. The results showed that there was more scatter in the dimensions in the wet part, and the deviation in size tended to be more pronounced for the thinner pillars for the wet print. On the other hand, the dry print showed a consistent deviation from the mean pillar thickness for all pillar sizes.

Figure 2: Graphs showing the deviation from the designed pillar size (left) and the deviation from the average pillar size (right) for wet and in-line dried calibration parts.

Figure 2 shows the deviation from the designed pillar thickness and the deviation from the average printed pillar thickness for wet and in-line dried calibration prints. The deviation from the average pillar thickness give a better indication of the scatter for simialr pillar sized. On average, both the wet and dry pillars tend to deviate less from the design value when the pillar size is smaller. This indicates that the deviation in both cases is not due to probably a result of the printing tolerances. However, both the absolute deviation and deviation from the mean show that there is more scatter in the dimensions of the wet part.

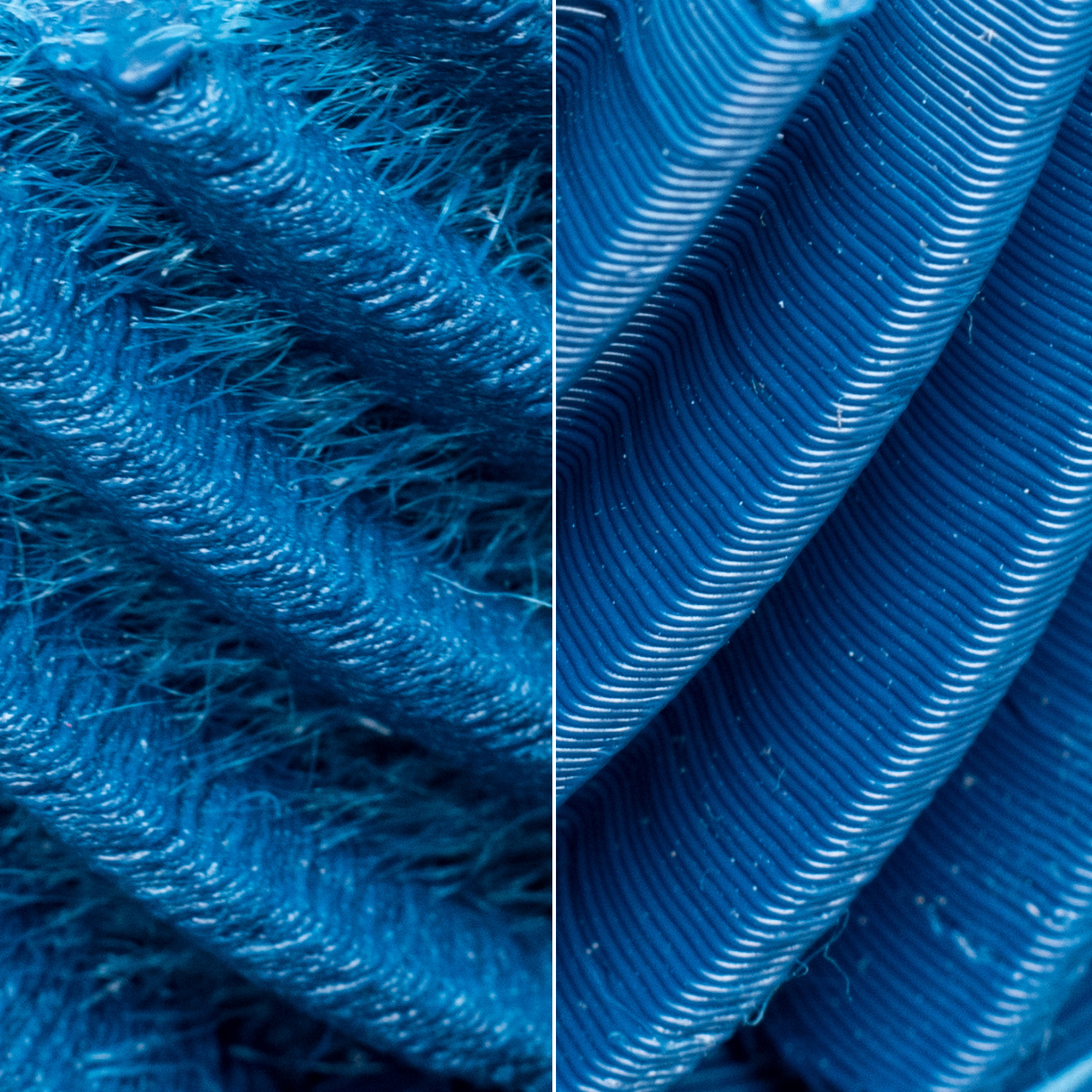

Furthermore, the deviation in size tends to be more pronounced for the thinner pillars for the wet print. The dry print tends to show a consistent deviation from the mean pillar thickness for all pillar sizes. When looking at a close up of the untreated wet part (Figure 3), it can be immediately observed that the thinner pillars are inconsistently extruded while those on the print treated with Drywise do not show such inconsistencies.

Figure 3: Macro shots to highlight surface finish, wet (left) and dried with Drywise (right).

The study also found that holes in parts printed with wet filament were smaller than those in the parts printed with dry filament (see Figure 4). This is because when printing with wet filament, the extruded material tends to expand slightly due to the trapped water vapor inside the material. As a result, the resulting prints will have a greater chance of not being within the tolerance limits if they are printed with untreated wet filament. We observed that holes deviated by about twice the amount compared to what the holes printed with dried material.

Figure 4: Graph showing the absolute deviation in hole size

Surface Finish and Dimensional Accuracy Implications

Example of Dimensional Accuracy

The clamp shown in Figure 5 was printed with Jabil PA0600 (black) and Addigy F1030 (natural) filaments. For the image on the right both filaments were dried using in-line drying. The image on the left was printed with the same filaments but not dried. Apart from the visual imperfections, the clamp which was not dried could not be easily screwed/unscrewed due to the variation in tolerances brought about by the presence of moisture in the material during printing.

Figure 5: Clamp printed with Jabil PA 0600 (Black) and Addigy F1030 (Natural) filaments. Untreated (left) and printed with Drywise in-line dryer (right).

Example of Surface Finish

The gear in Figure 6 was printed using untreated wet material and on the right through in-line drying with Drywise. The part on the left shows severe stringing and oozing, and a very poor surface finish. Furthermore the stringing and oozing inside the hole will also lead to the part not fitting on a shaft due to the increased material deposits affecting the tolerance of the hole. The part printed with in-line dried wet filament shows perfect surface finish and does not present any tolerance issues.

Figure 6: Gear printed with Jabil PA 0600, untreated (left) and printed with in-line dryer using Drywise (right).

Example of Interlayer Adhesion

Manifold part printed with wet material in Figure 7 shows severe printing artefacts and layer splitting due to the poor layer adhesion caused by inconsistent extrusion. On the other hand the part printed with wet filament treated using Drywise shows superior surface finish and has a higher overall strength.

Figure 7: Part printed using Luvocom 3F PA 50347 NT, untreated (left) and printed using in-line drying with Drywise (right).

Drywise In-Line Dryer

Issues like surface finish, dimensional accuracy and interlayer adhesion can be resolved by sufficiently drying material before 3D printing as excessive moisture in the filament is the main cause leading to the aforementioned issues. Another conclusion of this study was that nylon materials, even fresh out of the box have inconsistent levels of moisture, leaving the end-user guessing how much drying is needed to get the best results.

Drywise's in-line drying technology eliminates the guess work and can significantly improve the printing quality compared to other ways of drying filament. Drywise in-line drying improves the surface finish and dimensional accuracy of FDM prints, making it a tool to rely on in the world of 3D printing.