Hydration and Drying Challenges of Nylon 3D-printing Filaments

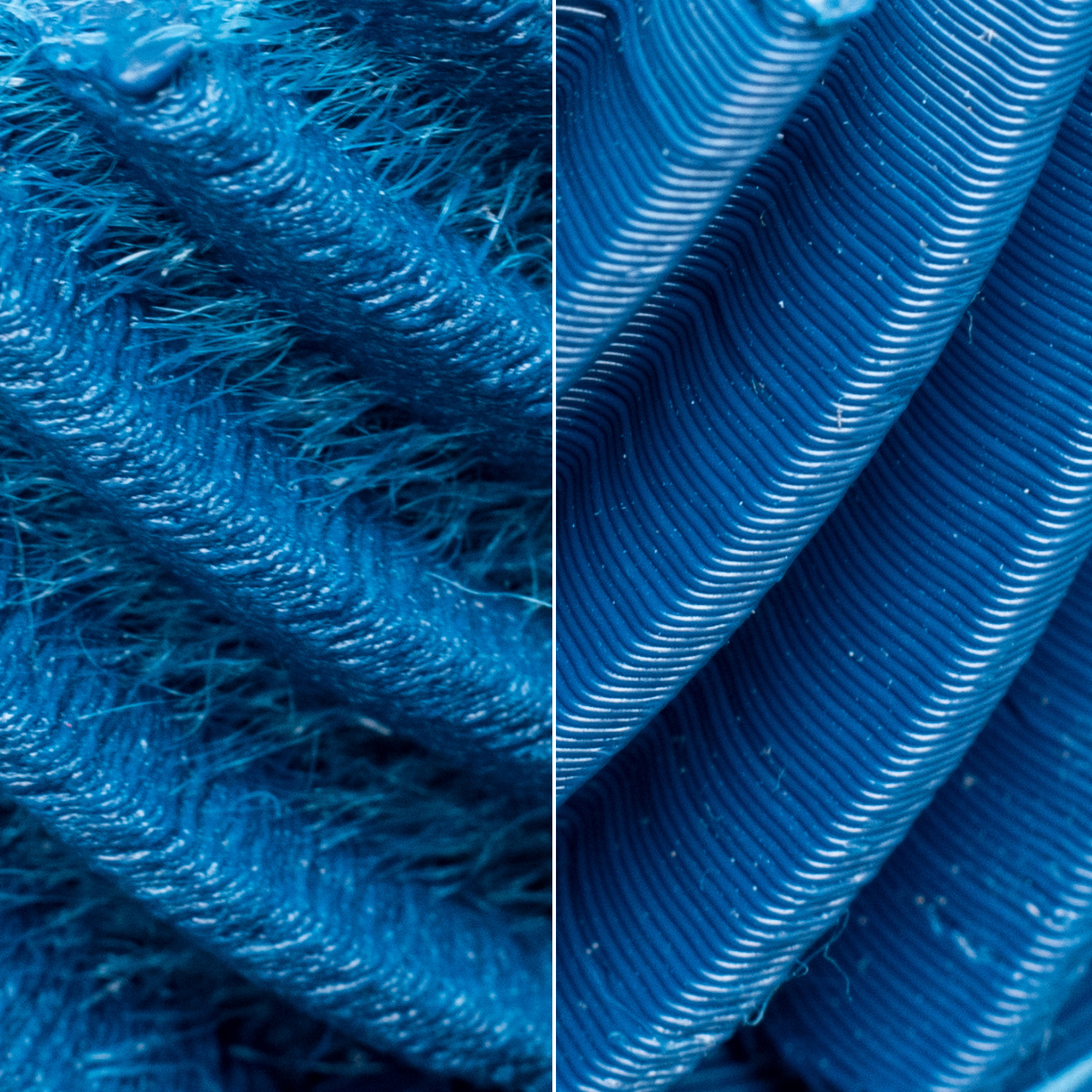

Hygroscopic materials, particularly those used in Fused Filament Fabrication (FFF), such as Nylon, have a significant susceptibility to moisture. This moisture absorption can drastically impact the quality and strength of the printed parts.

How quickly do nylon filaments absorb the ambient moisture

A moisture content as low as 0.5 w% can start showing first visible artifacts in the printed parts. At moisture level of 0.75 w% the defects become more noticable. Depending on the filament diameter, filament brand and its composition and the humidity levels, a relatively dry nylon filament can reach this moisture content within a span of 2 to 8 hours.

Image: Time it takes for filament of different diameter in different humidity environment e.g. 75% relative humidity vs 50% relative humidity to reach certain moisture level starting from 0.3 w% and how visible are the defects.

Filament packaging and challenges of newly opened nylons

Interestingly, even newly opened spools tend to have high enough moisture content to affect printing quality. The majority of these materials require drying before they can be used for artifact-free FFF printing.

It's also worth noting that filaments from the same manufacturer can have significantly different levels of moisture straight out of the package, leaving the user uncertain if the filament used is dry enough for printing.

Despite the rigorous packaging process claimed by many manufacturers, where filaments are dried to as low as 0.1 w%, our data paints a different picture.

Over 55% of neat nylon filaments were found to have moisture content above the 0.75 w% threshold, whereas the first instances of visual defects start showing up at moisture content of above 0.5 w%.

These levels of moisture content are significant enough to result in visible defects when the filament is printed straight from the package without any additional drying.

Image: Data of 71 neat nylons moisture content measured at point of opening them fresh form the packaging. Different letters represent nylon brands. Moisture content of Nylons marked with letter A is spread out from below 0.5 w% all the way to 3 w%.

How long does it take to dry nylons sufficiently

The process of printing with a hygroscopic material can be quite tedious. It often requires that a filament is dried before use and that the filament is kept in a low humidity environment such as a Dry box if a user intends to use the filament for more than a few hours. Conventional oven drying, as recommended by filament manufacturers, can take a significant amount of time to effectively lower the moisture level in a filament.

Manufacturers often provide users with vague instructions that state to dry materials for at least 4 hours at 80°C. However, our research suggests that this might not be sufficient. The drying process is not as straightforward as it seems. It is influenced by various factors including the filament diameter, the initial moisture content, and the drying environment.

For example, drying a neat nylon 6/66 1.75mm filament, from moisture content of 1 w% to 0.5 w% takes at least 24 hours. For 2.85mm filament, it takes 29 hours to achieve similar results.

This is because the drying rate in a conventional oven slows down as the filament starts to approach optimum humidity levels.

Image: Nylon 6/66 drying time to get them from 1 w% to 0.5 w%.

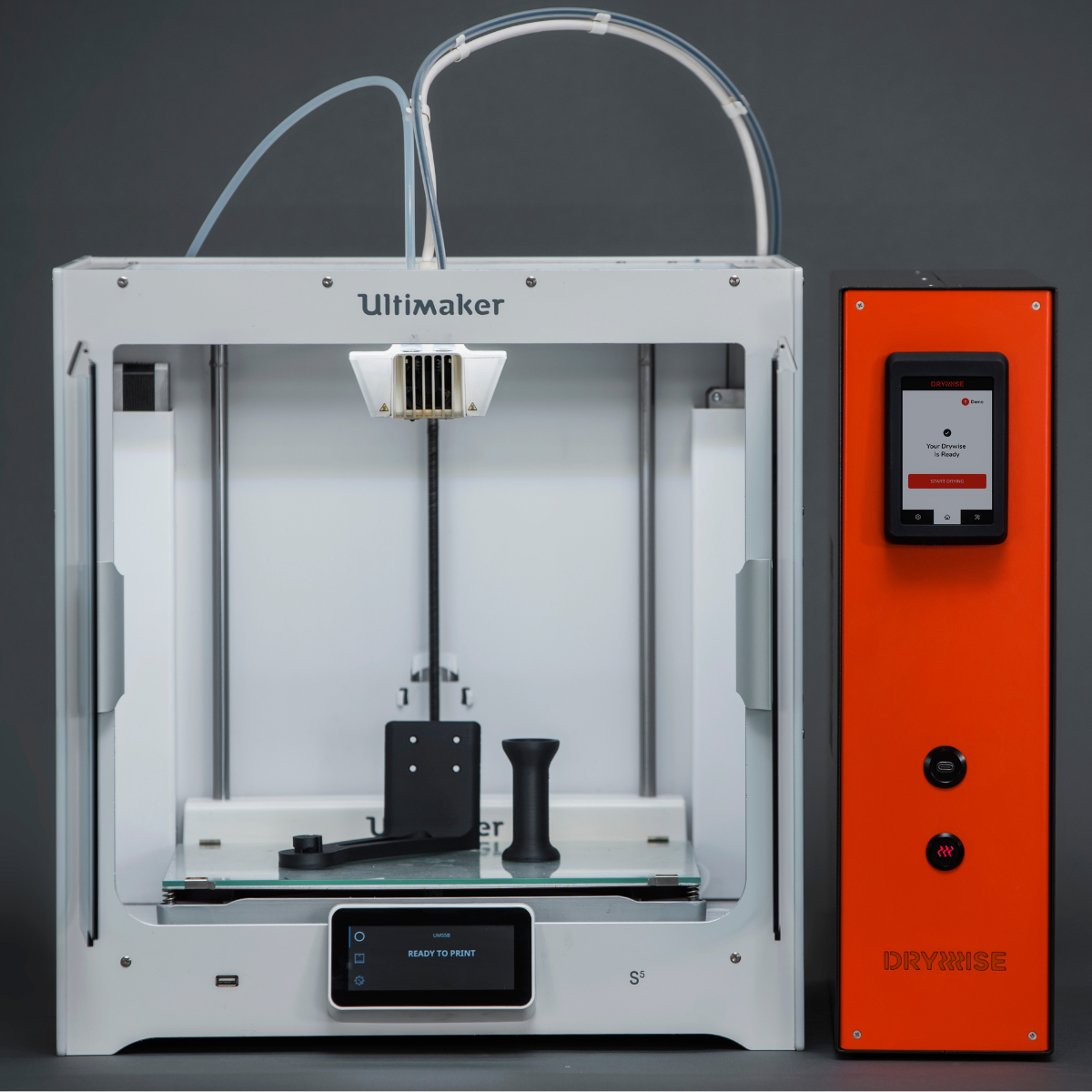

A better way to print hygroscopic materials

However, the in-line filament drying e.g. Drywise presents a more efficient solution. It can go from wet material to ready-to-print in less than one hour with minimal user input. The device comes with pre-calibrated drying profiles and guides the user for an easy, fool-proof drying experience. The built-in sensors and in-line drying architecture also monitor the filament throughout the drying process ensuring consistent and reliably dried material throughout the whole printing process.